描述

There are several types of mesh fencing commonly used when protecting a perimeter or facility, and they all offer an alternative to picket fence panels.

However, there are key differences between each mesh fence type that may affect the level of security they provide.

1. Chain link fence

Chain link fence (sometimes called chain link fence, chain link fence, cyclone fence, and razor wire fence) is a woven metal fence made of steel wire, usually galvanized.

The diamond-shaped “net” of the fence is formed by bending the steel wire into a zigzag shape, with one side of the “zigzag” hooking directly onto the wire and the other side of the “zigzag” hooking onto the wire.

Chain link fencing can provide an easy-to-install, cost-effective solution, but the nature of its manufacture may limit the number of design variations and styles available.

Additionally, depending on the diameter of the wire, the wire can be cut easily with the right equipment. Chain link fences also offer a level of “flexibility” that makes them easier to climb than other mesh fences.

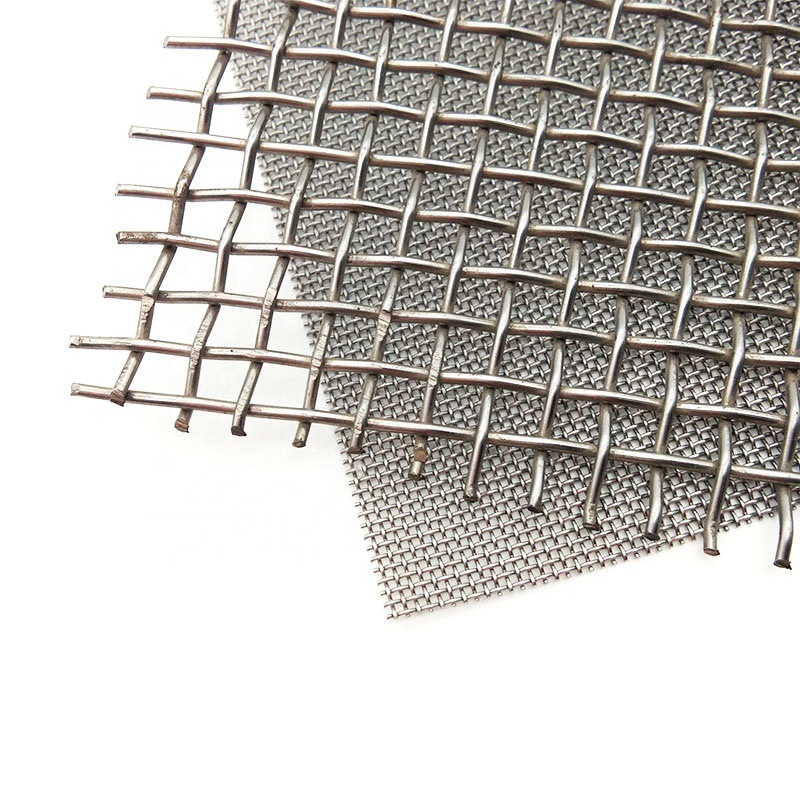

2. Woven wire mesh

Woven wire mesh fences are manufactured by creating a series of crisscrossing wires that are woven above and below vertical wires to create a grid.

This type of mesh fencing is commonly used in agriculture and can provide a relatively inexpensive option. Due to its design, woven wire mesh can bend without breaking and can therefore withstand considerable stress.

However, its wires can become loosened by stubborn intruders, and if cuts are made on the mesh, the wires can become separated from each other.

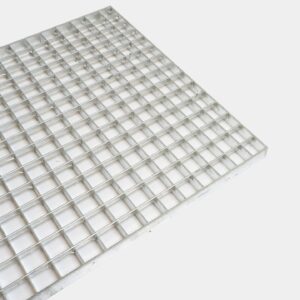

3. Welded wire fence

Welded wire fencing is made by electrically welding wires together to form a mesh or grid pattern, and is often used to protect at-risk buildings and infrastructure because it is stronger than chain link or woven wire fencing.

Like many mesh fencing options, it can withstand strong winds, and by using a mesh pattern with small holes, welded wire fencing can be designed to be difficult to climb as intruders will find it difficult to grab anything.

However, a determined intruder with the right tools can separate the welded wire fence at the weld, creating an opening large enough for a security breach to occur.

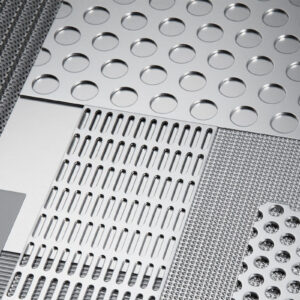

4. Expanded metal fencing

Expanded steel fence is manufactured by simultaneously cutting and stretching material fed from rolls or sheets. The fence panels are then cut to the desired size.

Expanded steel mesh offers many key advantages over chain link fencing, welded mesh fencing, and woven wire fencing solutions.

Expanded steel mesh is made from one piece of material, making it inherently strong. There’s nothing loose, no fretting wires or tight joints or welds. Therefore, it is more difficult to break through than a chain link fence or a welded wire fence.

Expanded mesh fence panels cannot be easily aimed at their welds, nor can they simply be separated with common tools such as a scissor jack. The uncut knuckles of expanded steel can withstand more stress than welds or joints.

Cutting expanded metal creates sharp edges around any gaps in the material. This makes passage more difficult and can deter intruders even if they manage to dig a hole large enough to get through. Unlike welded wire fencing, expanded metal fencing can be used on sloping ground without the need to step on it.